Anyị na-eji usoro enweghị dysprosium na ngwaahịa dị ala dị ala maka ndị ahịa iji belata ọnụ ahịa.Anyị nwere usoro kwụsiri ike nke enwere ike ịme ka ọ bụrụ ngwaahịa ọnụọgụ dị ala.Ọ na-ebelata ọnụ ahịa ma na-abawanye arụmọrụ n'ihu maka ndị ahịa na-ejikwa nlezianya na-achịkwa ndidi na nhazi na mkpuchi dị ka ihe dị iche iche chọrọ nke ndị ahịa iji hụ na nkwụsi ike nke nchebe plating n'otu oge ahụ, gụnyere nnu nnu, mkpuchi mkpuchi, njikọ colloid na ihe ndị ọzọ. .

Ngwaahịa gburugburu na-adịkarị mfe nkuku na-efu na usoro mmepụta.Ya mere, anyị nwere ngwa nyocha zuru ezu na-akpaghị aka maka ọdịdị ọdịdị ọdịdị, nke nwere ike hụ na ntụpọ ngwaahịa dị n'ime oke njikwa ma zere ngwaahịa ndị na-adịghị mma na iji usoro.

N'ihe banyere ngbanwe agbanwe agbanwe, anyị na-ahụ na ọkụ na-eme ka ọ bụrụ ihe na-agbanwe agbanwe na njikwa usoro ndọta, yana ngwa nleba anya zuru oke iji gbochie ngwaahịa magnetik na-adịghị ike ịgakwuru ndị ahịa.N'ihe gbasara nkwakọ ngwaahịa magnetization, ụlọ ọrụ anyị nwere akụrụngwa magnetization na-akpaghị aka iji gbochie ndị ọrụ ịfefe ụgwọ magnetik.

N'ihe banyere njikwa nnyefe, ọnụ ọgụgụ dị ukwuu nke igwe na-egbutu multi-line, slicing units, tozuru okè ọrụ nhazi nhazi, nlekota usoro ngwaahịa zuru oke, nzọụkwụ ọ bụla nke nhazi ngwaahịa na mmepụta nwere ike nweta nzaghachi ọganihu n'oge ọ bụla, tozuru okè cylindrical ngwaahịa akara, iji hụ na njikwa ndị ahịa chọrọ maka nnyefe ngwaahịa, yana ọganihu mmepụta ihe na-achịkwa.

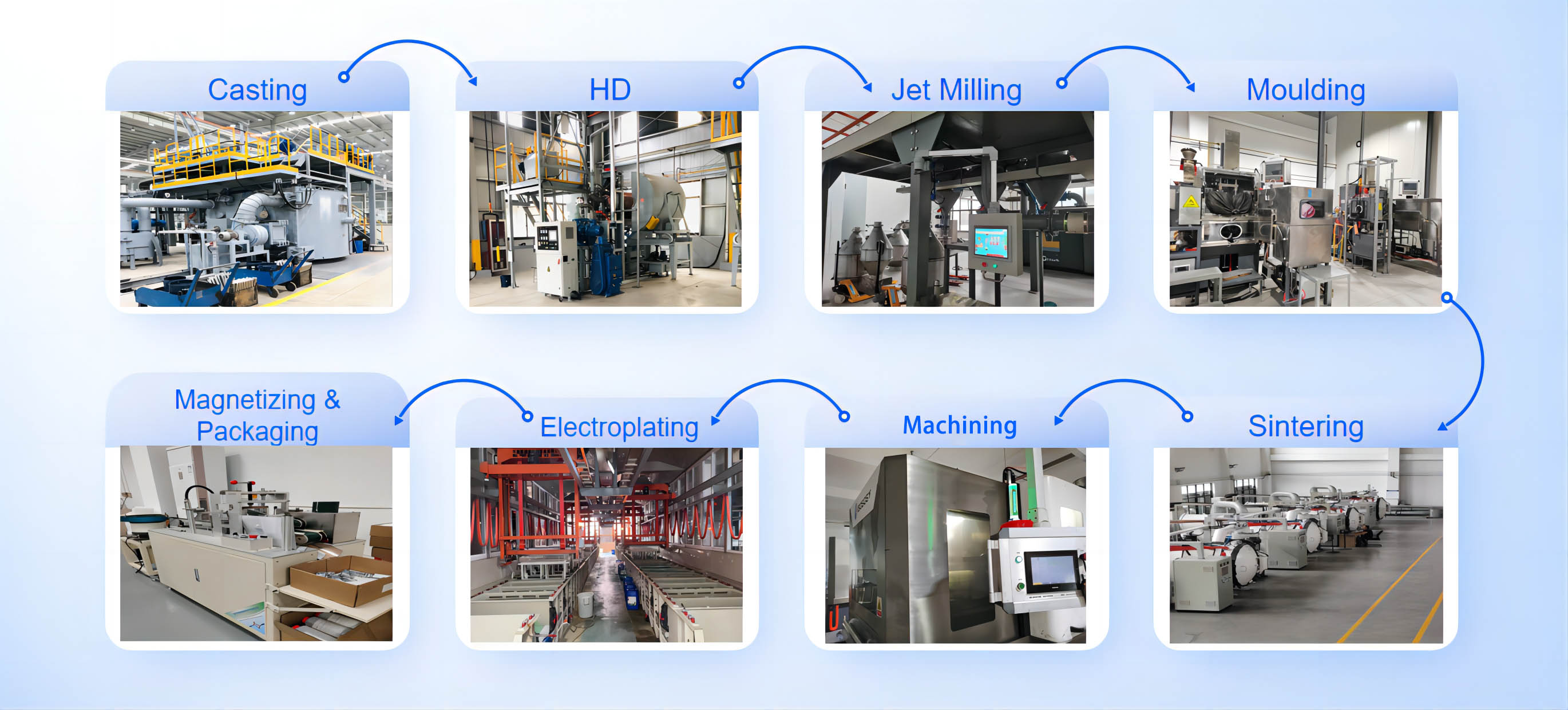

Usoro Mmepụta NdFeB

Okwu Mmalite

| Elu | Mkpuchi | Ọkpụrụkpụ μm | Agba | Oge elekere SST | Oge elekere PCT | |

| nikel | Ni | 10-20 | Ọla ọcha na-egbuke egbuke | > 24 ~ 72 | > 24 ~ 72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10-20 | Oji na-egbuke egbuke | > 48 ~ 96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5–8 | Brighe Blue Agba na-enwu | > 16 ruo 48 > 36 ~ 72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10-25 | Ọlaọcha | > 36 ~ 72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Ọlaedo | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Ọlaọcha | >12 | >48 | |

| Epoxy | Epoxy | 10-20 | Oji/isi awọ | >48 | --- | |

| Ni+Cu+Epoxy | 15-30 | > 72 ~ 108 | --- | |||

| Zn+Epoxy | 15–25 | > 72 ~ 108 | --- | |||

| Mmasị | --- | 1 3 | Ọchịchịrị Grey | Nchedo nwa oge | --- | |

| Phosphate | --- | 1 3 | Ọchịchịrị Grey | Nchedo nwa oge) | --- | |

Njirimara anụ ahụ

| Ihe | Oke | Uru ntụaka | Nkeji |

| Magnetik inyeaka Njirimara | Ọnụego ọnụọgụ mgbanwe nke Br | -0.08-0.12 | %/℃ |

| Ọnụego ngbanwe okpomọkụ nke Hcj | -0.42 ~ 0.70 | %/℃ | |

| Okpomọkụ akọwapụtara | 0,502 | KJ·(Kg ·℃)-1 | |

| Okpomọkụ Curie | 310-380 | ℃ | |

| Mechanical Physical Njirimara | Njupụta | 7.5-7.80 | g/cm3 |

| Vickers ike ike | 650 | Hv | |

| Nguzogide eletrik | 1.4x10-6 | μQ · m | |

| Ike mkpakọ | 1050 | MPa | |

| Ike ọdụdọ | 80 | Mpa | |

| Na-ehulata Ike | 290 | Mpa | |

| Nrụpụta okpomọkụ | 6 ruo 8.95 | W/m · K | |

| Modul nke Young | 160 | GPA | |

| Mgbasa ọkụ (C⊥) | -1.5 | 10-6/℃-1 | |

| Mgbasa ọkụ (CII) | 6.5 | 10-6/℃-1 |

Ngosipụta foto