Mgbe nhazichara, ọdịdị ahụ na-agbanwe agbanwe, na-agbanwe ma na-ehulata, na enwere ike ịkpụcha ọdịdị ahụ dịka nha achọrọ, a pụkwara iji PVC, nrapado, na mmanụ UV kpuchie ya dịka ihe ndị ahịa chọrọ.

Nnwale arụmọrụ ya na-agụnyekarị ọdịdị, nha, njirimara magnetik, polarity magnetik, ike ike, ike ndọda pụrụ iche, ike tensile, mgbochi ịka nká, ịrụ ọrụ ntụgharị.

Uru ya dị na nkwụsi ike ya dị mma, oke akụkụ ziri ezi;mmetụta dị mma na nguzogide vibration, ọ dịghị mfe imebi;obere ike ndọda nke na-eme ka ịdị arọ nke ngwaọrụ ahụ na igwe dum;enwere ike imepụta ya ka ọ bụrụ ndọta nwere ntụzịaka radial zuru oke (ụzarị zuru oke), yana enwere ike imepụta ya na ụdị dị iche iche magnet dị ka ogologo na nke dị mkpa, na mgbe nhazi ọkwa dị ka oghere, ịkpụ, ịkụ ọkpọ na ịgbagọ nwere ike ịrụ ọrụ ngwa ngwa. .

Ihe ọghọm ya bụ na magnetism adịghị ike nke ukwuu, ike ndọta na-amalite ibelata na 100 Celsius C, e wezụga nke ahụ, magnet roba nwere ọtụtụ ihe ọla dị ka neodymium na ígwè, nke ga-emebi emebi na nchara n'ikuku, na. njirimara okpomọkụ dị ntakịrị, ma ọ dị mfe ịkwatu.

A na-ejikarị ya na mkpuchi siri ike n'ọnụ ụzọ refrjiraeto, kabinet disinfection, kichin kichin, ihe ụmụaka ji egwuri egwu, ụlọ akwụkwọ, mgbasa ozi, igwe igwe na-eme ka oyi na-atụ kọmputa, igwe ikuku na-enye ntụ oyi, igwe na-ebi akwụkwọ, igwe na-ebi akwụkwọ, VCD na DVD mbanye, ikuku DC na-enweghị ahịhịa (nkwudo). ) Fans, magnetik Door akàrà, ihe ịchọ mma, nlekọta ahụike magnetik mattresses, magnetik mkparaMagnetic nwa oge ọkwọ ụgbọ ala maka ndị njem, Nrụnye nrụnye maka mbuli elu (n'ezie ọ bụla mbuli elu na-eji ibé akwụkwọ), Ụlọ akwụkwọ na ọhụrụ ngwaahịa (mma maka ihe mmekọrịta ọha na eze).

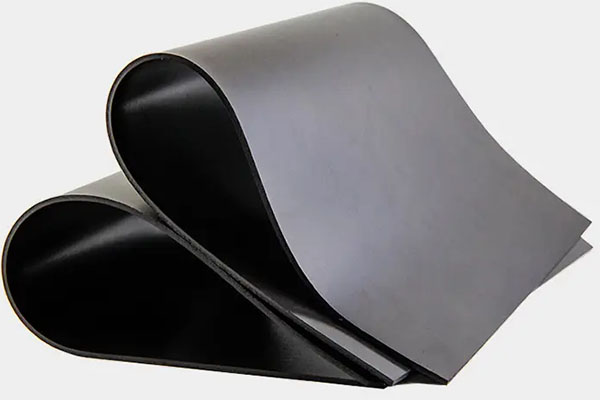

Njirimara anụ ahụ nke Igwe Ọdụdọ roba

| Curie okpomọkụ (℃) | 100 |

| Okpomọkụ kachasị arụ ọrụ (℃) | -40-80 |

| Hv (MPa) | 33-38D |

| Njupụta (g/cm3) | 3.6-3.8 |

Usoro mmepụta

Nyocha ihe

Ngwakọta ihe

Banburying

Na-etipịa

Ịkpụzi ihe

Nyocha na nkwakọ ngwaahịa

Ngosipụta arụmọrụ ihe nke magnet roba

| Nlereanya | Ụdị ngwaahịa | Arụmọrụ magnetik | Ngwongwo anụ ahụ | ||||||||||

| Br | BHc | Hcj | BHmax | Ike Tensile | Isi ike | Njupụta | Okpomọkụ | ||||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m³ | MGOe | kg/c | A | g/cm³ | ℃ | ||

| DMS001 | Isotropic extrusion magnetik eriri | 140-180 | 1400-1800 | 105-130 | 1320-1635 | 160-238 | 2010-3000 | 4-6.4 | 0.5-0.8 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS002 | Semi-anisotropic extrusion magnetik | 180-210 | 1800-2100 | 130-151 | 1635-1900 | 175-286 | 2200-3600 | 6.4-8.8 | 0.8-1.1 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS003 | Isotropic colendering roba magnet | 180-220 | 1800-2200 | 111-143 | 1400-1800 | 143-191 | 1800-2400 | 5.6-8.8 | 0.7-1.1 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS004 | Anisotropic extrusion magnetik eriri | 210-250 | 2100-2500 | 151-179 | 1900-2250 | 191-319 | 2400-4000 | 8.8-12 | 1.1-1.5 | ≥20 | ≥90 | 3.6-3.8 | -40-85 |

| DMS005 | Semi-anisotropic colendering roba magnet | 220-240 | 2200-2400 | 128-151 | 1600-1900 | 159-207 | 2000-2600 | 8.8-11.2 | 1.1-1.4 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS006 | Anisotropic colending roba | 240-270 | 2400-2700 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2-13.6 | 1.4-1.7 | ≥20 | ≥95 | 3.6-3.8 | -40-85 |

| DMS007 | Mpempe moto eletriki 500# | 240-270 | 2400-2700 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2-13.6 | 1.4-1.7 | ≥15 | ≥95 | 3.6-3.8 | -40-85 |

| DMS008 | Mpempe moto eletriki 300# | 240-265 | 2400-2650 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2-13.2 | 1.4-1.65 | ≥15 | ≥95 | 3.6-3.8 | -40-85 |

Ngosipụta foto