Ngwa: A na-ejikarị ya na moto na-enweghị brushes, moto ụlọ ọrụ magnet na-adịgide adịgide, moto textile, moto ụgbọ ala, moto na-adịgide adịgide na-adịgide adịgide, moto linear, ikuku compressor moto, igwe akụrụngwa na-adịgide adịgide magnet moto, Marine generator, magnet generator, na-adịgide adịgide magnet propulsion moto. , Ngwuputa magnet na-adịgide adịgide, moto njikọ, kemịkalụ magnet na-adịgide adịgide, moto ụgbọala maka EV, moto mgbapụta, moto EPS, ihe mmetụta na mpaghara ndị ọzọ.

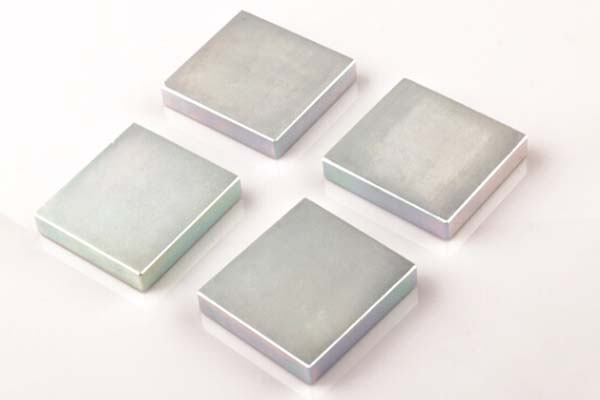

Product ahaziri: magnet na-niile ahaziri, ogologo nwere ike si 0.5mm-200mm, obosara si 0.5mm-150mm, ọkpụrụkpụ si 0.5mm-70mm, nke nwere ike izute ọtụtụ ahịa 'chọrọ.

mkpuchi: NdfeB magnet dị mfe oxidize, yabụ ọ na-achọkarị mkpuchi, mkpuchi nke a na-ejikarị n'ahịa dị ka:

1. ZN plating (ụdị mkpuchi ígwè, ule ịgba mmiri nnu nwere ike iru awa 24-48, arụmọrụ dị elu, ya mere ọ bụ otu n'ime nhọrọ kachasị mma maka ọtụtụ ndị ahịa).

2. NICUNI (ụdị mkpuchi metal, nnwale ịgba nnu nwere ike iru awa 48-72, arụmọrụ ọnụ ahịa dị elu karịa ZN, mana ka ejiri ya mee ihe n'ahịa ahịa ọnọdụ mgbakọ siri ike, ngwaahịa corrosion eguzogide chọrọ nke onye ahịa nwere ike. họrọ).

3. Epoxy (ihe mkpuchi na-abụghị ọla, ihe na-abụghị magnetik, nwere ike ibelata mfu moto eddy ugbu a, ule ịgba nnu nwere ike iru awa 72-96, ọnụ ahịa dị elu karịa ZN mkpuchi NICUNI.)

4. Ihe mkpuchi ndị ọzọ nke jikwa: Phosphate, Sn, Au, Ag, Parylene na ndị ọzọ ...

Nlere anya: Nọmalị, nnabata magnet anyị bụ +/- 0.05mm mgbe mkpuchi.

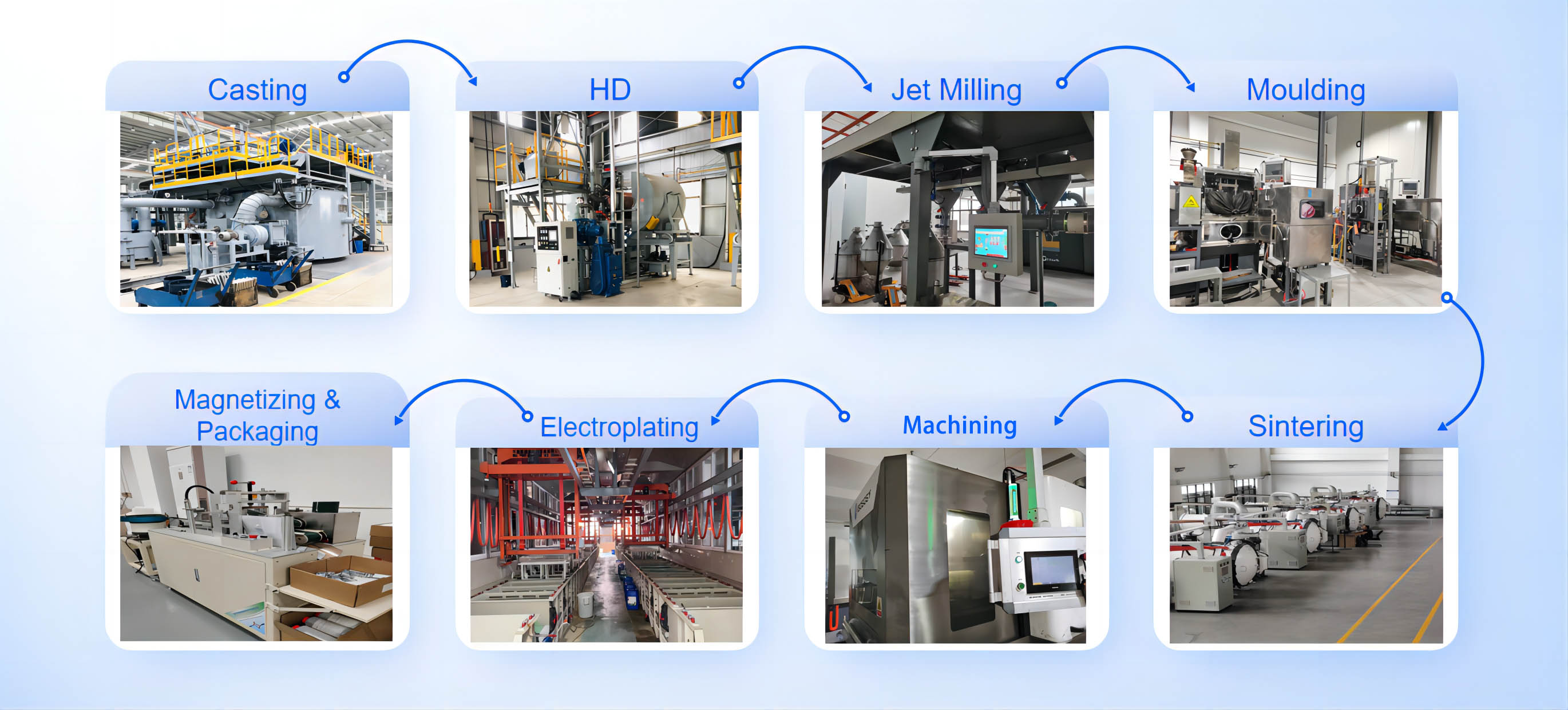

Usoro Mmepụta NdFeB

Okwu Mmalite

| Elu | Mkpuchi | Ọkpụrụkpụ μm | Agba | Oge elekere SST | Oge elekere PCT | |

| nikel | Ni | 10-20 | Ọla ọcha na-egbuke egbuke | > 24 ~ 72 | > 24 ~ 72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10-20 | Oji na-egbuke egbuke | > 48 ~ 96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5–8 | Brighe Blue Agba na-enwu | > 16 ruo 48 > 36 ~ 72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10-25 | Ọlaọcha | > 36 ~ 72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Ọlaedo | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Ọlaọcha | >12 | >48 | |

| Epoxy | Epoxy | 10-20 | Oji/isi awọ | >48 | --- | |

| Ni+Cu+Epoxy | 15-30 | > 72 ~ 108 | --- | |||

| Zn+Epoxy | 15–25 | > 72 ~ 108 | --- | |||

| Mmasị | --- | 1 3 | Ọchịchịrị Grey | Nchedo nwa oge | --- | |

| Phosphate | --- | 1 3 | Ọchịchịrị Grey | Nchedo nwa oge) | --- | |

Njirimara anụ ahụ

| Ihe | Oke | Uru ntụaka | Nkeji |

| Magnetik inyeaka Njirimara | Ọnụego ọnụọgụ mgbanwe nke Br | -0.08-0.12 | %/℃ |

| Ọnụego ngbanwe okpomọkụ nke Hcj | -0.42 ~ 0.70 | %/℃ | |

| Okpomọkụ akọwapụtara | 0,502 | KJ·(Kg ·℃)-1 | |

| Okpomọkụ Curie | 310-380 | ℃ | |

| Mechanical Physical Njirimara | Njupụta | 7.5-7.80 | g/cm3 |

| Vickers ike ike | 650 | Hv | |

| Nguzogide eletrik | 1.4x10-6 | μQ · m | |

| Ike mkpakọ | 1050 | MPa | |

| Ike ọdụdọ | 80 | Mpa | |

| Na-ehulata Ike | 290 | Mpa | |

| Nrụpụta okpomọkụ | 6 ruo 8.95 | W/m · K | |

| Modul nke Young | 160 | GPA | |

| Mgbasa ọkụ (C⊥) | -1.5 | 10-6/℃-1 | |

| Mgbasa ọkụ (CII) | 6.5 | 10-6/℃-1 |

Ngosipụta foto